Medical customers adopt Stratasys 3D Printer

Stratasys公司有限公司宣布,它已成功出售and installed the J750 Digital Anatomy 3D printer at healthcare institutions and medical service providers in major markets across the globe, including the United States, China, Italy, Spain, and Australia. Seattle Children’s Hospital, VA Health Care System, Nicklaus Children’s Hospital in Miami, Medilife and BIO3DModel in Italy, and Tknika and AIJU in Spain all recently turned to the innovative new system to help improve patient care and accelerate medical innovation.

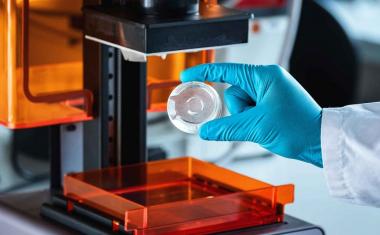

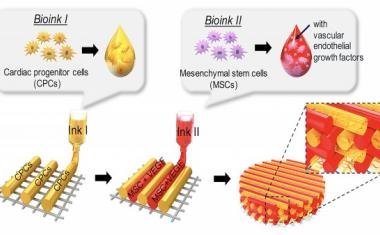

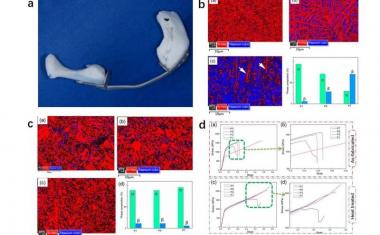

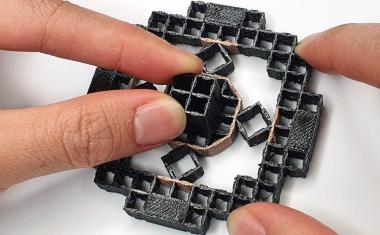

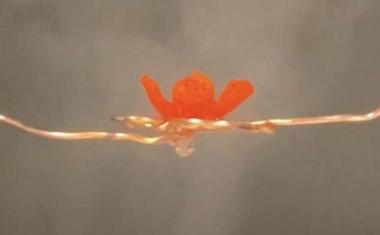

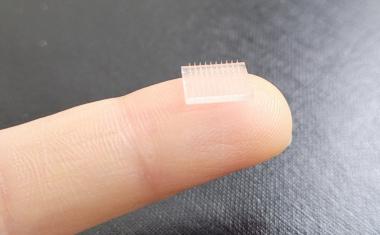

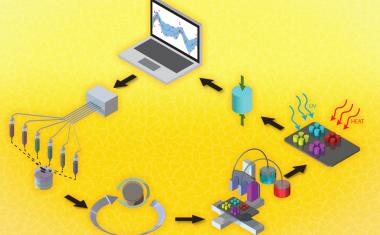

The J750 Digital Anatomy 3D printer produces anatomical models that mimic the actual feel, responsiveness, and biomechanics of human anatomy. Models can be punctured, sutured, cut, and physically manipulated like actual human tissue. This capability minimizes the use of animals and cadavers for clinical trials and surgical training. Hospitals, healthcare institutions and medical schools can use these lifelike3D modelsto improve clinical evaluation for a wide range of pathologies, as well as bring newmedical devicesto market faster.

Seattle Children’s Hospital purchased a J750 Digital Anatomy 3D printer early this year and installed it in its new 3D Printing Lab. A major motivation for getting the printer was the ability to create very soft models in-house to duplicate things like airways, livers, and hearts. “The earliest prints using TissueMatrix material were instrumental for understanding the optimal fit for a custom tracheostomy tube, something that would have been impossible with the best materials that we had access to only six months ago,” said Seth Friedman, Ph.D, Manager of InnovationImagingandSimulationModeling in the Improvement and Innovation Department. “I believe that by making models in parallel to a patient’s care journey we can truly make a difference. Now integrated into a systemic program called Custom Care, we have little doubt this new technology will help us provide the best care possible to our patients and families.”

Nicklaus Children’s Hospital upgraded to the new J750 Digital Anatomy 3D printer from an existing Eden 260 in theCardiovascular SurgeryProgram. The upgrade was a collaboration between the NCHS Personalized Medicine Initiative and the Cardiovascular Surgery Advanced Research Projects Laboratory and was made possible by the support of the Bailey Foundation and donors to NCHS.

Dr. Redmond Burke, chief of Cardiovascular Surgery and co-director of the Heart Program, said it’s now a critical part ofsurgical planning. “It’s very valuable to be able to actually cut open a model to get a very clear vision of what we’ll see in the operating room,” he said. “We believe this is a significant advance that will allow us to reduce the trauma of patients undergoing complex heart surgery.” He said the new 3D printer also opens up completely new avenues in teaching and patient care.

In Spain, two technology institutions have invested in the Digital Anatomy 3D printer to pioneer their medical service offering. Both cite the unrivalled ultra-realism and tactile nature of the models as a significant competitive advantage. Nacho Sandoval, Additive Manufacturing Lead at AIJU, said, “Previously, we could not produce models replicating the organic materials frequently requested by the medical sector, let alone realistically simulating the behaviors of human tissue. What is also remarkable is that the precision of the Digital Anatomy printer offers higher resolutions than those obtained with a CT or MRI, which are usually above half a millimeter. We’re already seeing vast interest from a wide range of medical practitioners for these types of models in real-world applications.”

Gorka Baqueriza,Additive Manufacturing项目经理,中欧Tknika,补充说:“我们看到这个ology having a significant impact in several areas of healthcare – frommedical trainingto pre-surgery planning to patient care. The level of realism that can be achieved for such a wide range of anatomical models and pathologies is incredible.”

Recommended article

The role of surgical 3D printing in hospitals

More and more hospitals are entering the world of 3D printing in surgery as decision-makers and surgeons are realising the immense benefits for surgeons and patients alike.

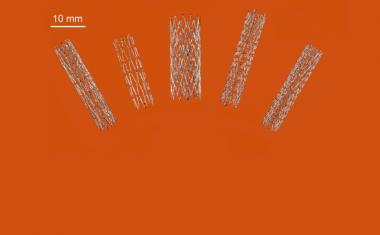

In Italy, President of BIO3DModel, Eng. Roberto Rizzo, said he has witnessed particular interest in the Digital Anatomy 3D printer forsurgical training. “This technology enables a drastic reduction in time training surgeons, in particular the ability to investigate for any specific pathological conditions prior to the actual surgery,” he stated. “For example, until now it was not possible to produce hollow vascular systems down to 1mm wall thickness and diameter. This incredible detail could be the difference between life or death for a patient.”

Emanuele D’Angeli, General Manager, Medilife, adds: “The models produced on the Digital Anatomy 3D printer offer the same soft touch and variable density of actual human tissues and organs, which today is impossible to achieve with any other existing 3D printing technology. We are currently testing several applications, including the creation of an artificial limb. The aim is to reproduce the natural external appearance of the limb in terms of texture and color shade, while also replicating the lifelike physical feel that we experience with human touch.”

Source:Stratasys